What is Crankshaft Position Sensor?

The Crankshaft Position Sensor (CKP) is an essential electronic component in an internal combustion engine. It plays a crucial role in monitoring the rotational speed (RPM) and position of the crankshaft. This information is vital for the Engine Control Module (ECM) to manage fuel injection and ignition timing systems.

Bad Crankshaft Position Sensor (CKP) Symptoms

A malfunctioning Crankshaft Position Sensor can manifest in various symptoms, indicating potential issues with the vehicle’s performance:

- Check engine light illuminated: A malfunctioning crankshaft position sensor can cause the check engine light to illuminate on the dashboard. This happens because the engine control unit (ECU) detects issues related to the crankshaft position sensor and triggers relevant fault codes. A detailed list of fault codes related to crankshaft position sensor issues is covered in this blog.

- Engine Misfire: The CKP sensor provides critical information to the ECU. If it malfunctions, the ECU may miscalculate the timing of the spark and fuel injection, leading to misfires. As a result, you may notice rough idle with noticeable vibrations while your car is stationary, such as when you’re at a red light or stop sign.

- Lack of Power: Incorrect data from a faulty CKP sensor can disrupt the optimal operation of the engine. This happens because the incorrect data confuses the ECM, causing it to send erroneous spark and fuel instructions. This results in reduced combustion efficiency, leading to a noticeable lack of power during acceleration.

- Intermittent stalling while idling or driving: If your car has a bad crankshaft position sensor, you may notice the engine stalling unexpectedly. This happens because erratic signals from the faulty CKP sensor can cause the ECU to mismanage the engine timing, leading to unexpected stalling.

- Jerking While Driving: Another symptom of a faulty crankshaft position sensor is your car jerking or stuttering unexpectedly while driving. This happens due to erratic signals from the sensor, causing the ECU to misfire and disrupt the engine’s smooth operation.

- Poor Fuel Efficiency: A faulty crankshaft position sensor can disrupt the fuel injection timing, causing the engine to run inefficiently and burn more fuel than necessary. This leads to increased trips to the gas station as your vehicle consumes more fuel than usual.

Common Crankshaft Position Sensor fault codes

Here is a list of codes that are associated with the bad Crankshaft Position Sensor to look for if your check engine light has turned on

- P0008: Engine Positions System Performance Bank 1

- P0009: Engine Position System Performance Bank 2

- P0016 Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor A)

- P0017 Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor B)

- P0018 Crankshaft Position – Camshaft Position Correlation (Bank 2 Sensor A)

- P0019 Crankshaft Position – Camshaft Position Correlation (Bank 2 Sensor B)

- P0335 Crankshaft Position Sensor A Circuit Malfunction

- P0336 Crankshaft Position Sensor A Circuit Range/Performance

- P0337 Crankshaft Position Sensor A Circuit Low Input

- P0338 Crankshaft Position Sensor A Circuit High Input

- P0339 Crankshaft Position Sensor A Circuit Intermittent

What Causes the Malfunction of Crankshaft Position Sensor ?

Causes of a Faulty Crankshaft Position Sensor

- Mechanical Damage: Physical damage to the sensor or its components can impair its ability to function correctly. This can result from impacts, vibrations, or improper handling during maintenance.

- Break in the Tone Ring: The tone ring, also known as the timing wheel, works in conjunction with the CKP sensor to provide accurate readings of the crankshaft’s position. If the tone ring develops cracks or breaks, it can disrupt the sensor’s ability to correctly read the crankshaft’s position, leading to inaccurate or erratic data being sent to the ECM.

- Internal Short Circuits: Electrical issues within the sensor itself, such as short circuits, can prevent it from sending correct signals to the engine control unit (ECU).

- Electrical issue: Poor connections across electrical connectors, broken wiring, blown fuses, loss of ground, or issues with previously repaired wires can disrupt the connection with the CKP Sensor.

How To Test Crankshaft Position Sensor?

Testing a Crankshaft Position Sensor (CKP) involves different procedures depending on whether you have a two-wire (magnetic) sensor or a three-wire (Hall effect) sensor. Here’s a step-by-step guide for each type:

Testing a Two-Wire (Magnetic) Crankshaft Position Sensor

- Disconnect the Sensor: Begin by disconnecting the crankshaft position sensor from its electrical connector and unmounting it from the engine. Ensure the engine is off and the ignition key is removed to avoid any accidental short circuits or electrical issues.

- Connect the Multimeter Probes: Attach the multimeter probes to the two terminals on the sensor. Ensure a secure connection to get accurate readings.

- Set the Multimeter to Resistance Mode : Set your multimeter to the resistance (ohms) mode. This mode is typically denoted by the Greek letter omega (Ω).

- Measure the Resistance: Measure the resistance across the sensor terminals using the multimeter. The multimeter should display a resistance value.

- Evaluate the Results: Refer to the vehicle’s repair manual for the specific resistance value range for the crankshaft position sensor. If the resistance is out of the specified range, consider replacing the sensor as it may be faulty.

Testing a Three-Wire (Hall) Crankshaft Position Sensor

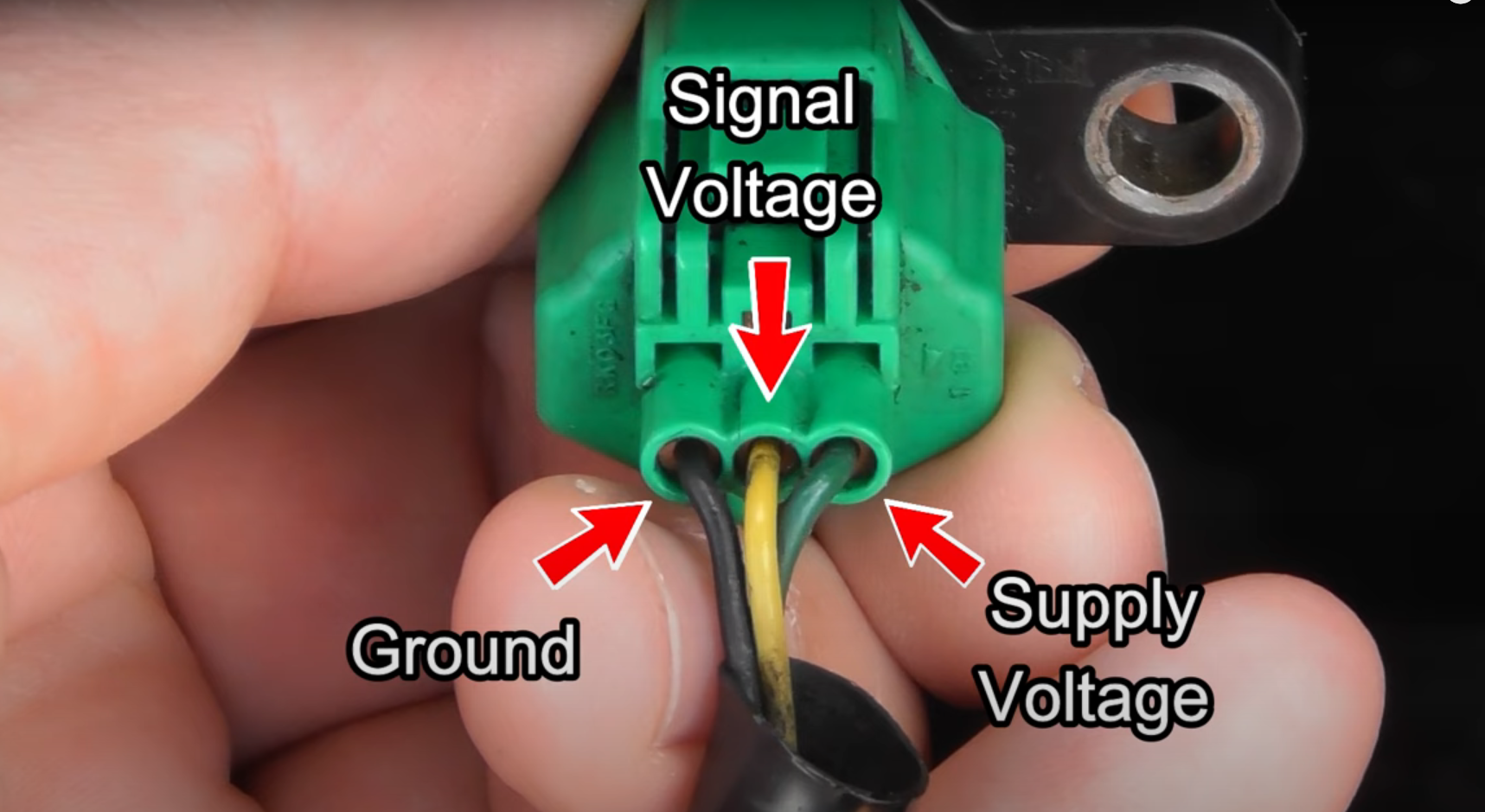

A three-wire crankshaft position sensor is a bit more complex than a two-wire sensor. It has three wires: a power supply, a signal, and a ground wire. Testing a three-wire CKP sensor involves checking for proper voltage supply, signal output, and ground connection.

- Checking the Connection Line for Short Circuit to Ground

- Disconnect the sensor plug and the control unit plug.

- Use a multimeter to measure the resistance between the sensor plug terminals and the vehicle ground.

- Reference value should be greater than 30 MOhm

- Disconnect the sensor plug and the control unit plug.

- Checking the Voltage Supply of the Sensor

- Refer to the vehicle wiring diagram to identify the voltage supply wire.

- With the ignition in the ON position (engine not running), use a multimeter to measure the voltage supply from the control unit to the sensor.

- Refer to the vehicle wiring diagram to identify the voltage supply wire.

- Checking the Output Voltage

- Identify the signal wire and ground wire.

- Connect the multimeter probes across the signal wire and ground wire.

- Take a metal piece and bring it near to the sensor. Observe the voltage reading. The voltage should be zero when the metal piece is near the sensor. The voltage should show full supply voltage when the metal piece is far from the sensor.

- Identify the signal wire and ground wire.

Other Issues That Exhibit Similar Symptoms as a Bad Crankshaft Position Sensor (CMP)

When a car exhibits the symptoms mentioned above, and the Crankshaft Position Sensor has been checked and found to be in working order but the issue persists, it’s essential to inspect the other components of the engine timing system.

- Faulty Camshaft Position Sensor: A malfunctioning camshaft position sensor can exhibit symptoms similar to those of a faulty crankshaft position sensor. The camshaft position sensor is responsible for detecting the position and speed of the camshaft. It plays a crucial role in determining the timing of the spark and fuel injection. When it fails, it can disrupt the engine timing, resulting in symptoms such as rough idling, poor acceleration, and decreased fuel efficiency.

- Faulty Variable Valve Timing (VVT) solenoid: A malfunctioning VVT solenoid can exhibit symptoms similar to those of a defective crankshaft position sensor. The VVT solenoid adjusts the timing of the intake and exhaust valves on the crankshaft to optimize engine performance.

- Faulty Spark Plug: A faulty spark plug may not produce a spark at the optimal time due to issues such as carbon buildup or a corroded electrode.

- Faulty Timing Chain or belt: A faulty timing chain or belt, which connects the camshaft and the crankshaft in a vehicle engine and coordinates the opening and closing of the engine’s valves, can also exhibit symptoms similar to a bad crankshaft position sensor. A faulty timing chain or belt can disturb the valve opening and closing times, leading to rough idling, poor acceleration, and decreased fuel efficiency.