What is Throttle Position Sensor?

A throttle position sensor (TPS) is an essential component in the engine’s electronic control system, monitoring the position of the throttle valve in the throttle body. Positioned on the butterfly spindle or shaft, it directly measures throttle angle, the rate at which the throttle opens and closes, and the closed throttle position during idle. [1]

The TPS measures real-time throttle position data to the engine’s Electronic Control Unit (ECU). This information, combined with inputs from other sensors like the Mass Air Flow (MAF) sensor and the Manifold Absolute Pressure (MAP) sensor, helps the ECU calculate air density entering the engine. This data is crucial for determining the optimal timing for injector opening and adjusting the spark advance, ensuring the engine maintains the ideal air-fuel ratio of 14.7:1 for efficient combustion and performance.

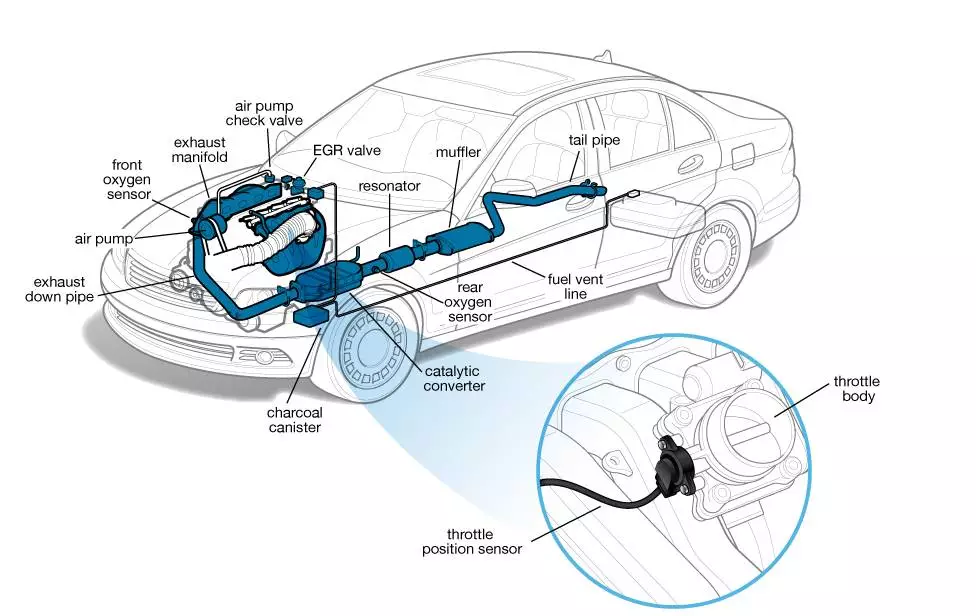

Where Is the Throttle Position Sensor Located?

The throttle position sensor is typically located on the throttle valve spindle, which is part of the throttle body. The throttle body itself is positioned between the air cleaner and the intake manifold of the engine.

Bad Throttle Position Sensor (TPS) Symptoms

A malfunctioning Throttle Position Sensor (TPS) can manifest in various symptoms, indicating potential issues with the vehicle’s performance:

- Check engine light illuminated: A malfunctioning TPS sensor can trigger the check engine light to illuminate on the dashboard.

- Engine performance may be affected, leading to rough running or hesitation: With a faulty TPS sensor, the Engine Control Module (ECM) may not receive necessary sensor data related to the throttle angle, the rate at which the throttle opens and closes to maintain the air/fuel ratio at 14.7:1. This can result in rough running or hesitation, impacting the overall performance of the engine.

- Visible exhaust emissions: Visible exhaust emissions may be observed while driving due to a lean or rich air-fuel mixture resulting from the faulty TPS sensor.

- Engine stalling: Intermittent engine stalling may occur due to a faulty TPS.

- Lack of power: Lack of power during acceleration may occur due to the faulty TPS, which affects the engine air intake system.

- Poor Fuel Efficiency: Inefficient fuel consumption may be observed as a symptom of the faulty TPS, as it affects the proper regulation of the air/fuel ratio due to absence of TPS sensor data . This can result in the wastage or improper utilization of fuel.

Common TPS fault codes

Here is a list of codes that are associated with the bad TPS to look for if your check engine light has turned on

- P0068 : MAP/MAF – Throttle Position Correlation

- P0120 : Throttle Position Sensor/Switch A Circuit Malfunction

- P0121 : Throttle Position Sensor/Switch A Circuit Range/Performance Problem

- P0122 : Throttle Position Sensor/Switch A Circuit Low Input

- P0123 : Throttle Position Sensor/Switch A Circuit High Input

- P0124 : Throttle Position Sensor/Switch A Circuit Intermittent

What Causes the Malfunction of Throttle Position Sensor (TPS) ?

Causes of a Faulty Throttle Position Sensor (TPS)

- Electrical Wire Issues: Poor connections across electrical connectors, broken wiring, blown fuses, loss of ground, or issues with previously repaired wires can disrupt the connection with the TPS.

- Carbon build-up: Over time, carbon deposits can accumulate on the throttle plate, causing it to stick or bind within the throttle body.

- Excessive Oil Mist: If excessive oil mist from the crankcase ventilation system contaminates the MAP sensor, it can interfere with its functionality.

- Water Ingress: Exposure to water, particularly from driving through deep puddles or heavy rain, can cause water to enter the TPS sensor housing, leading to malfunction.

- Exposure to Road Salt: Vehicles driven in areas where road salt is used for de-icing purposes are prone to corrosion, which can affect the TPS’s performance over time.

How To Test Throttle Position Sensor (TPS)?

Testing the Throttle Position Sensor can be done using following method:

- Check Voltage using multimeter:

- Set the multimeter to voltage mode.

- Connect the red probe of the multimeter to the signal wire of the TPS sensor connector. Refer to your vehicle’s wiring diagram to identify signal wire.

- Connect the black probe of the multimeter to a good ground point, such as the battery negative terminal or the engine block.

- Turn on the ignition key without starting the engine.

- Check the voltage reading on the multimeter. The voltage should typically read between 0.5 and 1.5 volts. If the voltage is outside of this range, it indicates a faulty TPS that needs replacement.

- Set the multimeter to voltage mode.

- Check Resistance using multimeter

- Switch the multimeter to the ohm mode.

- Connect the probes of the multimeter to the power and ground wires of the TPS connector. Typically, the power wire is red and the ground wire is black, but refer to the wiring diagram to confirm.

- Ensure that the ignition key is turned off to prevent any electrical interference.

- Measure the resistance between the power and ground wires. The multimeter should typically read between 200 and 600 ohms.

- If the resistance falls outside of this range, it indicates a faulty TPS that requires replacement.

- Switch the multimeter to the ohm mode.

Other Issues That Exhibit Similar Symptoms as a Bad Throttle Position Sensor (TPS)

When a car exhibits the symptoms mentioned above, and the Throttle Position Sensor (TPS) has been checked and found to be in working order but the issue persists, it’s essential to inspect the other components of the air intake monitoring system.

- Faulty Mass Air Flow (MAF) Sensor: A malfunctioning MAF sensor can exhibit symptoms similar to those of a faulty TPS. The MAF sensor is responsible for measuring the mass of incoming air and plays a crucial role in determining the air/fuel mixture ratio. When it fails, it can disrupt fuel delivery to the engine, resulting in rough idling, sluggish acceleration, and reduced fuel efficiency.

- Faulty Manifold Absolute Pressure (MAP) Sensor: A defective MAP sensor can produce similar symptoms to those of a bad MAF sensor. The MAP sensor measures the pressure within the intake manifold and assists in determining the air/fuel mixture ratio. If it malfunctions, it can disrupt the engine’s fuel delivery and cause issues such as rough idling, poor acceleration, and decreased fuel efficiency.