Manufacturer Specific Trouble Codes

Power Train Generic Code

What does the P0008: Engine Position System Performance Bank 1 mean?

The P0008 code means that the engine timing is not functioning properly. Essentially, it indicates that the Engine Control Module (ECM) has detected a misalignment between the camshaft bank 1 and crankshaft positions.

When the P0008 Triggers?

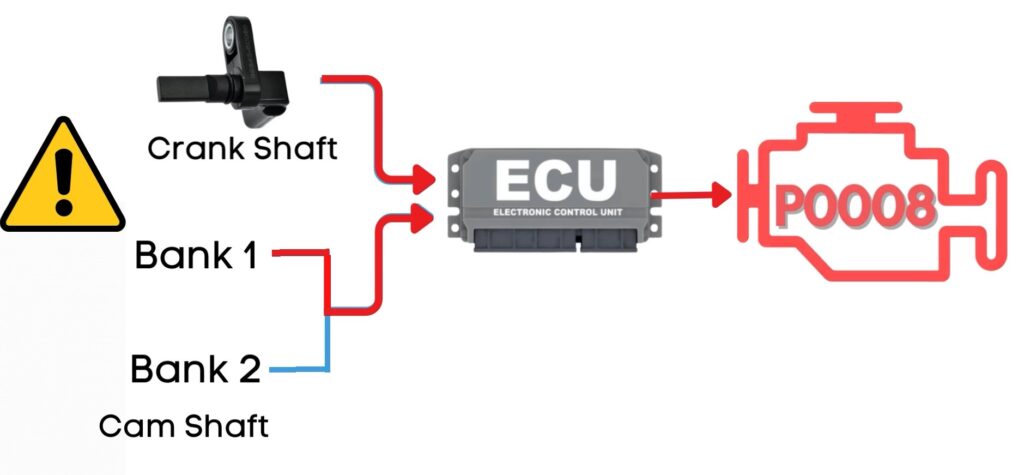

The crankshaft position sensor measures the position of the crankshaft, and the camshaft position sensor measures the camshaft’s position. Both signals are sent to the ECU.

In the case of V6 or V8 engines, there are two camshafts: Bank 1 and Bank 2.

When the ECU detects a misalignment between the Bank 1 camshaft position sensor and the crankshaft position sensor, it triggers OBD-II code P0008.

What are the Symptoms of P0008 code?

The common symptoms of the P0008 code include:

- Check Engine Light: The check engine light comes on if there are any active trouble codes related to EMS.

- Poor engine performance: Problems in the engine timing system can lead to incorrect injection timing and ignition timing. This can manifest as Rough idle, Hesitation, Reduced power, Sluggish acceleration.

- Decreased Fuel Efficiency: Wrong injection and ignition timing due to P0008 lead to incomplete combustion of fuel, which leads to poor fuel economy.

What causes the P0008 code?

Causes of the P0008 code can vary and include the following:

- Bad Camshaft Position Sensor: Due to the malfunction of the camshaft position sensor, the ECU may detect an engine timing error, which may trigger P0008 and other OBD-II codes related to camshaft position sensors along with symptoms of a bad camshaft position sensor.

- Read more about: Bad Camshaft Position Sensor: Symptoms & Causes.

- Read more about: Bad Camshaft Position Sensor: Symptoms & Causes.

- Bad Crankshaft Position Sensor: Like a malfunctioning camshaft position sensor, a faulty crankshaft position sensor can also cause the ECU to detect an engine timing error. This may trigger P0008 and OBD-II codes related to the crankshaft position sensor and other symptoms of a bad crankshaft position sensor.

- Read more about: Bad Crankshaft Position Sensor: Symptoms & Causes.

- Read more about: Bad Crankshaft Position Sensor: Symptoms & Causes.

- Bad VVT solenoid: Due to bad VVT solenoid the camshaft position advance and delay may not work properly. Which may trigger P0008 and other OBD-II codes related to VVT solenoid along with symptoms of a bad VVT solenoid.

- Read more about: Bad VVT solenoid : Symptoms & Causes.

- Read more about: Bad VVT solenoid : Symptoms & Causes.

How to Diagnose & Fix the P0008 Code?

Diagnosing the P0008 code requires specialized diagnostic tools and equipment. However, here are some methods you can use yourself to diagnose and potentially fix the issue:

- Check for Other Codes:

- Diagnose: Look for any additional diagnostic trouble codes (DTCs) that may be present. These could provide clues about related issues contributing to the P0008 code.

- Fix: Address any other codes that are present, as resolving these may also resolve the P0008 code.

- Diagnose: Look for any additional diagnostic trouble codes (DTCs) that may be present. These could provide clues about related issues contributing to the P0008 code.

- Check for Electrical Wire Issues:

- Diagnose: Inspect the electrical wiring related to the engine timing system for any signs of damage, such as frayed wires, loose connections, or corroded terminals. Check fuses and relays related to the camshaft sensor, camshaft sensor, VVT solenoid etc.

- Fix: Replace any damaged wiring, tighten loose connections, and replace any blown fuses or faulty relays.

- Diagnose: Inspect the electrical wiring related to the engine timing system for any signs of damage, such as frayed wires, loose connections, or corroded terminals. Check fuses and relays related to the camshaft sensor, camshaft sensor, VVT solenoid etc.

- Inspect the Timing Belt:

- Diagnose: Visually inspect the timing belt and its associated components for any signs of damage, such as tears, cracks, or excessive wear.

- Fix: If any physical damage or wear is found, replace the timing belt.

- Diagnose: Visually inspect the timing belt and its associated components for any signs of damage, such as tears, cracks, or excessive wear.

- Inspect Camshaft and Crankshaft Position Sensors:

- Diagnose: Use a diagnostic scanner to check the signals from the camshaft and crankshaft position sensors. Ensure they are working correctly and within specifications.

- Fix: Replace any faulty sensors that are providing incorrect signals.

- Diagnose: Use a diagnostic scanner to check the signals from the camshaft and crankshaft position sensors. Ensure they are working correctly and within specifications.

- Check for Engine Oil Condition:

- Diagnose: Inspect the engine oil for contamination or low levels. Proper oil quality and levels are essential for the timing components to function correctly.

- Fix: Change the engine oil and filter if it is dirty or low. Use the correct grade of oil as specified by the manufacturer..

- Diagnose: Inspect the engine oil for contamination or low levels. Proper oil quality and levels are essential for the timing components to function correctly.

How to Prevent the P0008 Code?

To prevent the occurrence of the P0008 code, it’s important to implement routine maintenance and take proper care of the fuel system. Here are some preventative measures:

- Regular Inspection and Cleaning of the Fuse Box: Regularly check the fuse box for any signs of corrosion, dirt, or damage. Clean any corrosion or buildup on the electrical connections using an appropriate cleaner. Ensure the connections are secure and free from debris that could disrupt the electrical flow.

- Regular Inspection of the Timing Belt/Chain: Inspect the timing belt for signs of wear, cracks, or fraying. Replace it according to the manufacturer’s recommended interval.

- Regular Oil Changes: Use the correct grade of oil as specified by the vehicle manufacturer. High-quality oil helps ensure that the timing components, such as the tensioner and guides, operate smoothly. Follow the recommended oil change interval.